Trichloroisocyanuric acid is an organic compound with the formula (C3Cl3N3O3). It is a new generation of high-efficiency broad-spectrum disinfectants, bleaches and anti-shrinkage agents. Mainly used for disinfection of drinking water, industrial circulating water, swimming pools, silkworm, restaurants, hotels, public places, homes and hospitals. Among them, the efficiency of bactericidal are much better than that Sodium hypochlorite.

Currently, it’s a highest grade in the disinfectants industry. The product has strong oxide effect on almost all fungi, bacteria, viruses, spores, etc., with it lower cost, also safe and convenient to use. it widely used in food, dairy products, rice seed treatment, fruit preservation, and egg disinfection. also be used for fish disease control, fiber bleaching, wool shrinkage prevention, daily chemical bleaching, wood mildew, paper bleaching, rubber chlorination and battery materials.

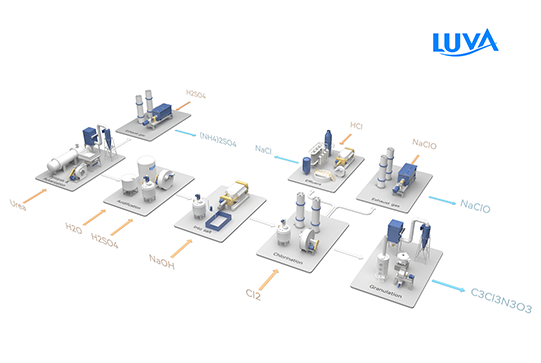

The technologies of Trichloroisocyanuric acid plant provided by Luva is an advanced “Multistage Countercurrent Type” continuous chlorination process with the lowest consumption of chlorine gas at less than 1.05 tons per ton of TCCA.

The TCCA production facility consists of a calcium (CA) production unit and a TCCA production unit.

We design TCCA plant on continuous process. Comparing to traditional Batch production process, continuous process is advantageous of higher product quality. Continuous production is also more stable comparing to Batch plant.

| S/N | Item | Unit | Value | Remark |

| 1 | Available chlorine, wt% | %(w/w) | ≥90 | – |

| 2 | pH (Aqueous sol. of 1%) | N/A | 2.6–3.2 | – |

| 3 | H₂O | %(w/w) | ≤0.5 | – |

| S/N | Item | Unit | Guarantee Value | Remark |

| 1 | CA Unit | – | – | – |

| 1.1 | Urea | T/T Product | ≤1.8 | – |

| 2 | TCCA Unit | – | – | – |

| 2.1 | CA | T/T Product | ≤0.63 | – |

| 2.2 | Chlorine | T/T Product | ≤1.05 | – |

| 2.3 | Caustic Soda (100%) | T/T Product | ≤0.72 | TCCA Unit |

Mature Continuous Chlorination Process:

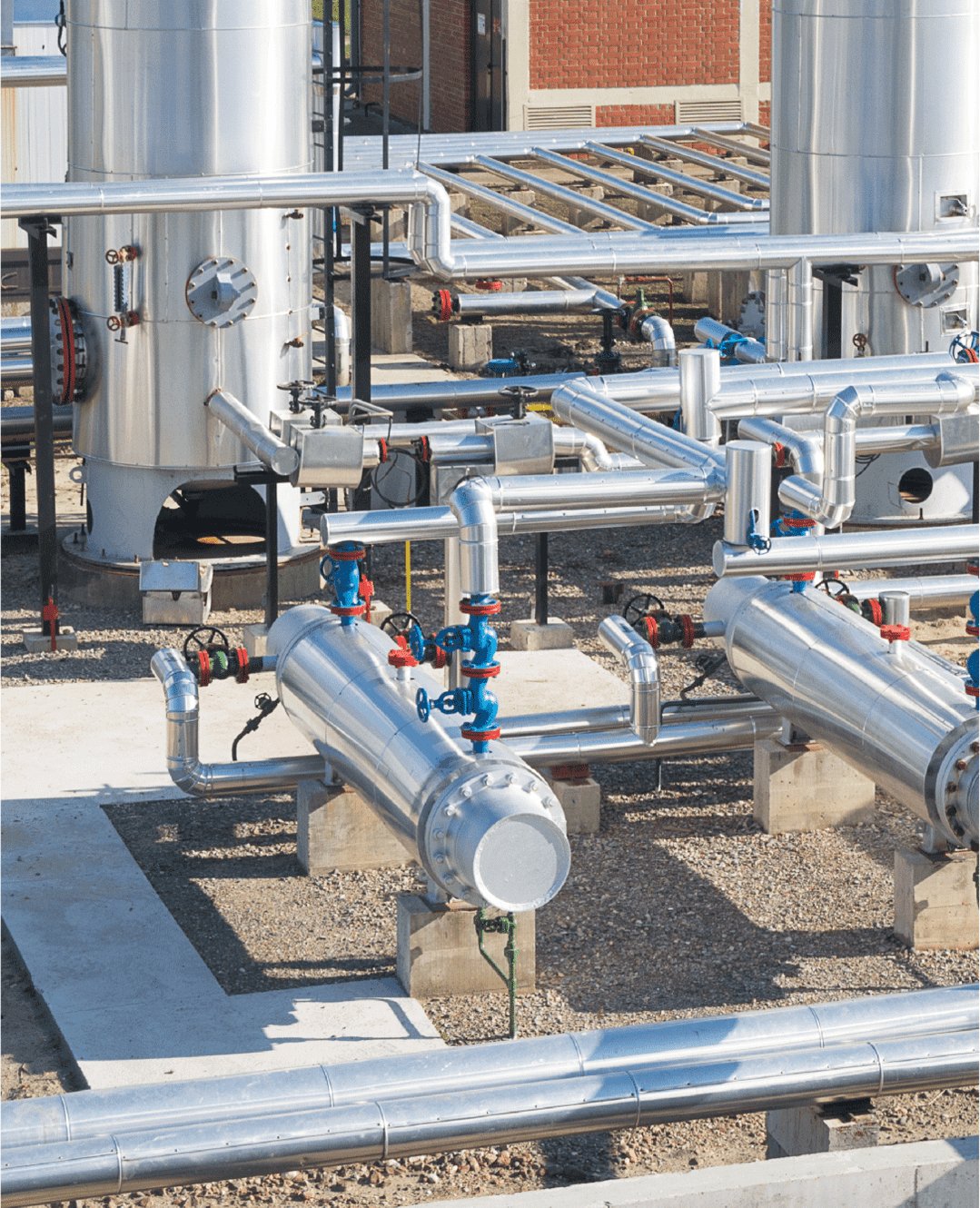

The core equipment, a titanium chlorination reactor, ensures optimal conditions for the chlorination reaction. This maturity in the process enhances reliability and efficiency.

High Utilization Rate of Chlorine Gas:

The specially structured chlorine gas distributor and split cooling device improve the utilization rate of chlorine gas, reducing the cost associated with recovering or treating escaped chlorine gas.

Reduced Generation of NCl3:

Optimization of the process significantly reduces the generation of NCl3, addressing production safety concerns.

Optimal Raw Material Ratio:

Continuous testing to obtain the best raw material mix enhances product purity.

Intelligent Control System (PLC/DCS):

Enhances automatic operation and control capabilities, reducing manual intervention and ensuring employee safety.

Strict Quality Control Plan (QCP):

Ensures high standards throughout the project execution stage.

After-sales Service and Technical Support:

KAPSOM’s commitment to lifelong after-sales service and remote technical support ensures sustained, efficient operation.

Key equipment like the chlorination reactor and centrifuge are made of titanium, known for its high resistance to acids, alkalis, and chlorine, ensuring longevity.

This prevents environmental pollution, yields low humidity in separated solid material, and ensures high production quality.

Offers high screening accuracy and efficiency, adjustable discharge port for sorting different particle sizes, and a unique structure to prevent clogging and facilitate easy maintenance.

Emphasizes the durability and long-term utility of the equipment.

Occupies less space and performs multiple tasks such as separation and washing, enhancing operational efficiency.

Committed to health, safety, and environmental training and management for the owner's employees.

Serving as a bleaching agent and disinfectant, TCCA is employed to maintain the hygiene and cleanliness of swimming pool water.

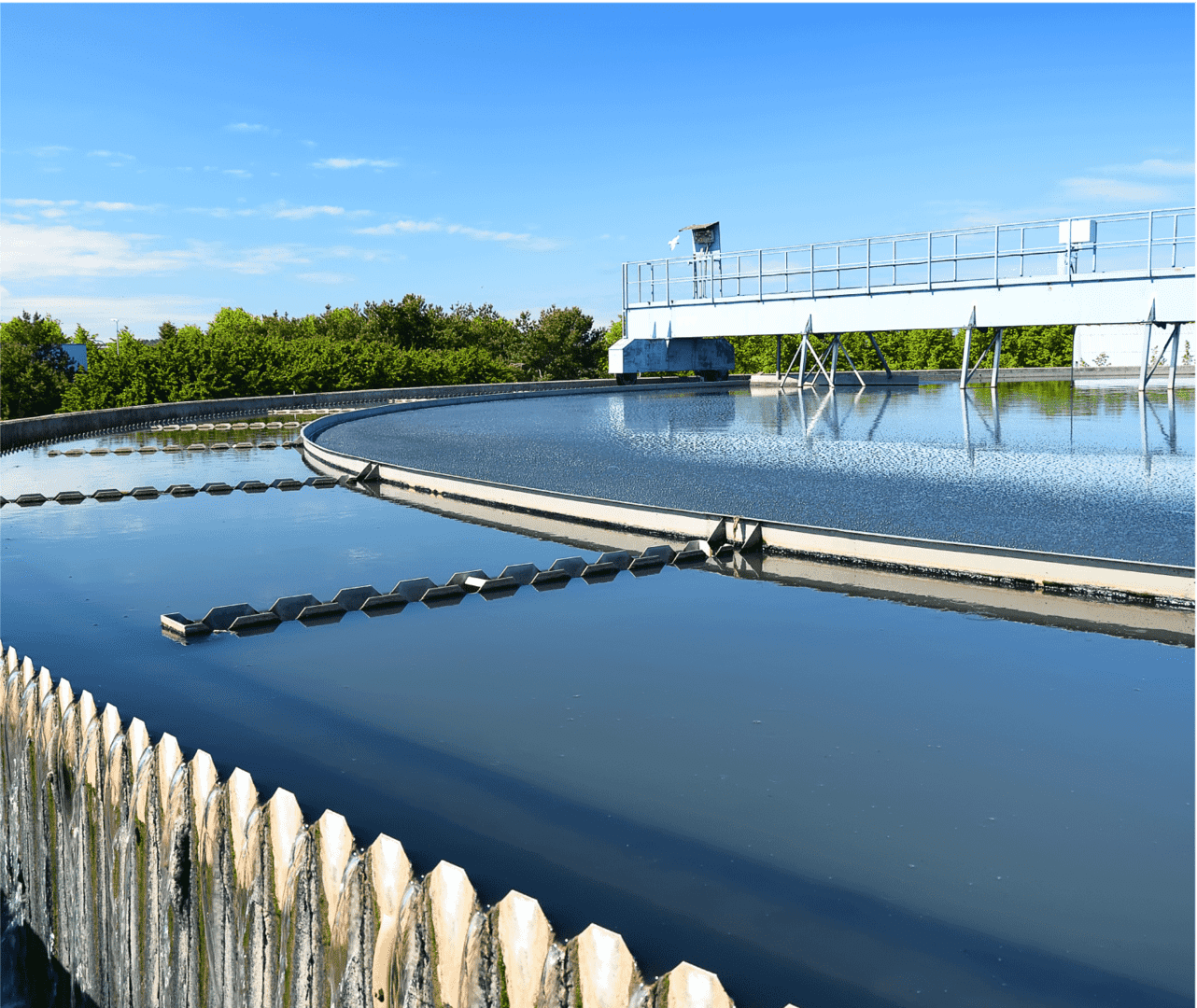

Water Treatment: Trichloroisocyanuric Acid (TCCA) is extensively utilized in water treatment processes, encompassing the disinfection and purification of swimming pools,

In the agricultural sector, TCCA can be employed for seed treatment, disinfection of agricultural irrigation systems, and water treatment in

In certain industrial processes, TCCA is also used as a disinfectant and bleach during the production processes.

TCCA is regarded as a method for emergency water source treatment, such as disinfection of water sources after natural disasters.

TCCA is applicable for hygiene and disinfection purposes in environments such as landfill sites, public spaces, and healthcare facilities.