Approximately 80% of the total cost of a factory project is determined during the process design phase. Together, process design and technology form the basis of modern industrial operations, aiming to optimize production, minimize resource consumption

and ensure the sustainability and competitiveness of manufacturing processes.

Provide comprehensive technical consulting services through a professional team to assist customers in solving complex technical problems and developing practical solutions.

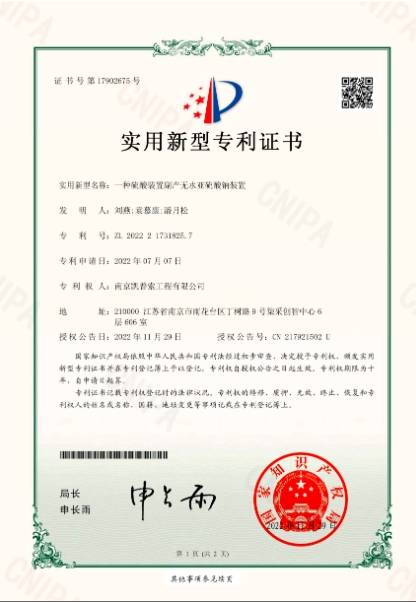

LUVA is actively committed to innovation and development and has established a R&D center. Through in-depth process optimization research, we strive to improve production efficiency, reduce costs, and improve product quality and sustainability through innovative processes. The LUVA R&D Center will continue to provide innovative solutions, including advanced material research and development and intelligent technology applications, to meet the evolving needs of customers.